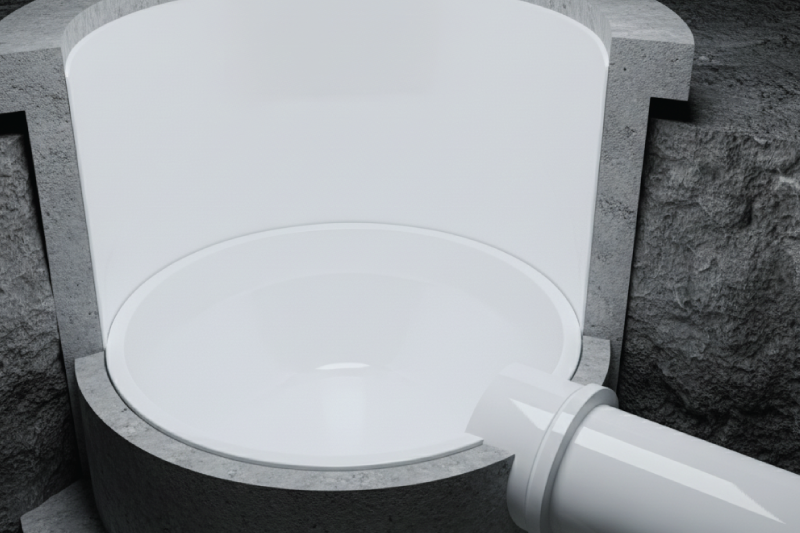

GRP Lining on RCC Manholes, Drains & Sump Pits

Durable. Waterproof. Corrosion-Resistant.

GRP lining is the most effective long-term solution for protecting concrete and metallic structures exposed to water, sewage, and aggressive chemicals. At Al Muraqib FIber Glass Ind L.L.C, we specialize in GRP lining for RCC manholes, sump pits, and drainage systems — providing seamless waterproofing and corrosion protection that lasts a lifetime.

Why GRP Lining is Essential

Concrete and metal surfaces in underground utilities are constantly exposed to moisture, gases, and harsh substances. Over time, this leads to corrosion, leakage, and surface deterioration.

GRP (Glass Reinforced Plastic) lining forms a tough, impermeable barrier that prevents:

-

Water seepage and leakage through microcracks and joints.

-

Corrosion caused by hydrogen sulfide, acids, and salts.

-

Algae and bacterial growth that degrade concrete and contaminate water.

-

Structural damage from long-term chemical exposure.

Key Benefits

-

Permanent Waterproofing: Creates a seamless and watertight layer that eliminates absorption and leakage.

-

Chemical & Corrosion Resistance: Protects against sewage gases, wastewater, and industrial effluents.

-

Smooth Finish: Ensures unhindered water flow and minimizes blockages in drains.

-

Long Service Life: Extends structure durability by decades with minimal maintenance.

-

Quick Installation: Suitable for both new and existing manholes, sumps, and drain systems.

-

Cost-Effective: Reduces frequent repair and replacement costs.

Typical Applications

-

RCC Manholes: Protect inspection and access chambers from corrosion and infiltration.

-

Sump Pits: Ensure waterproofing and prevent structural damage caused by standing water or chemicals.

-

Drainage Channels: Provide smooth, corrosion-free surfaces for wastewater or stormwater management systems.

GRP Lining Process

-

Surface Preparation: Cleaning, repairing cracks, and roughening the concrete surface for adhesion.

-

Priming: Applying a polyester or vinyl ester resin layer to improve laminate adhesion.

-

Fiberglass & Resin Application: Layering high-quality fiberglass mat with polyester or vinyl ester resin to the required thickness.

-

Topcoat Application: Applying UV and chemical-resistant topcoat for final sealing.

-

Inspection & Testing: Checking for pinholes, thickness uniformity, and adhesion integrity.

Quality Assurance

All GRP lining works by Al Muraqib are executed as per international standards. Our projects undergo:

-

Adhesion & continuity tests to confirm surface bonding.

-

Visual and thickness inspection to ensure consistency.

-

Consultant approvals for potable and industrial applications.

Project Experience

Al Muraqib has executed GRP lining works for municipal drainage networks, industrial facilities, and hospitality projects across the UAE. Our proven track record includes consultant-approved installations with long-term client satisfaction.

Maintenance & Lifespan

Once installed, GRP lining requires minimal maintenance. Periodic inspection ensures long-term performance with an expected lifespan under normal operating conditions.